Product Details

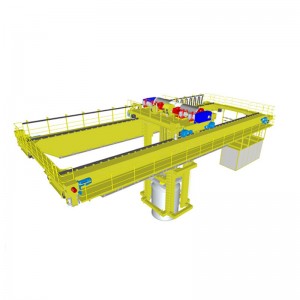

Forging Casting Workshop Overhead Crane

-

Load capacity

180t~550t

-

Crane span

24m~33m

-

Lifting height

17m~28m

-

Working duty

A6~A7

Overview

Overview

Forging is the process of shaping metal using heat and pressure. The forging overhead crane is an essential piece of equipment in any forging operation. It is designed to lift and move heavy loads of metal from one place to another with ease. The crane is typically made of high-strength steel and is capable of lifting weights that range between 5 and 500 tons, depending on the size and capacity of the crane.

In addition, the forging crane is capable of working at high elevations, making it ideal for moving large pieces of metal from one floor of a forging facility to another. It is also designed to operate in extreme conditions, including high temperatures and harsh environments, making it a reliable and durable tool for any forging operation.

The use of the forging overhead crane has revolutionized the forging process, making it more efficient and safer for workers. With the crane, workers no longer have to manually lift heavy loads, which can lead to strain and injury. Instead, the crane does the heavy lifting for them, allowing workers to focus on other important tasks.

Furthermore, the use of the forging crane has increased productivity in forging facilities. With the crane, workers can move heavy loads quickly and efficiently, allowing them to complete more tasks in less time. This, in turn, increases the overall output of the facility, resulting in increased profits and growth.

In conclusion, the forging overhead crane is an important tool in the forging industry. Its advanced technology, durability, and efficiency make it an essential piece of equipment for any forging operation.

Gallery

Advantages

Project Recommend

Related Products

Contact

If you have any questions, you are welcome to call and leave a message We are waiting for your contact 24 hours.

Inquire Now

Get Price

Get Price Contact Us

Contact Us Chat Online

Chat Online