Product Details

10 Ton Single Girder Overhead Crane

-

Load capacity:

1~20t

-

Crane span:

4.5m~31.5m or customize

-

Working duty:

A5, A6

-

Lifting height:

3m~30m or customize

Overview

Overview

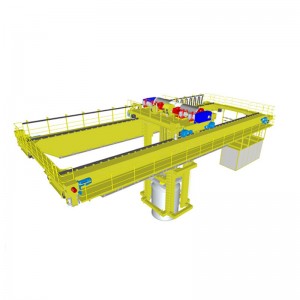

The 10 ton single girder overhead crane is divided into three parts: the lifting mechanism, the trolley running mechanism and the large trolley running mechanism. The lifting mechanism is used to vertically lift heavy objects. The trolley running mechanism is used to carry heavy objects for lateral movement. The crane traveling mechanism is used to move the lifting trolley and the load longitudinally. In this way, the bridge crane can carry and load and unload goods in three-dimensional space.

SEVENCRANE 10 ton single girder overhead crane adopts compact structure design and is applicable to various plant structures. This type of crane can lift up to 20 tons and span up to 31.5 meters. Even in highly restricted buildings, we can also equip the crane with a low headroom electric hoist to meet your needs. At the same time, this type of crane does not need to reserve a safe distance under the ceiling. Therefore, the limited indoor space can be used to the maximum extent and the investment cost of the plant can be saved.

SEVENCRANE single-beam bridge crane can be equipped with H-shaped steel girder and box girder to adapt to complex working conditions. Moreover, it has a variety of connection modes of main beam and end beam, so the crane can adapt to different plant structures and ensure that the hook can reach the best height. In addition, our complete set of crane components can meet your different needs.

• Lifting capacity up to 20 tons.

• Span up to 31.5 meters (depending on lifting capacity).

• Different end beam connection modes can be adapted to different plant structures.

• The hook can meet the requirement of the highest lifting height.

• Different control modes can be selected: cabin control, remote control, pendent control.

Gallery

Advantages

Project Recommend

Related Products

Contact

If you have any questions, you are welcome to call and leave a message We are waiting for your contact 24 hours.

Inquire Now

Get Price

Get Price Contact Us

Contact Us Chat Online

Chat Online